Centre de Téléchargement

-

Fiches de Produits

-

Notre Division 27

-

Outil d'analyse du retour sur investissement pour la documentation relative au confinement des allées

-

Brochure sur les marchés que nous desservons

Environmental contamination represents one of the most underestimated yet devastating threats to data center operations. While temperature and humidity control dominate facility management discussions, airborne particulates, corrosive gases, and metallic contaminants silently compromise equipment reliability, accelerate hardware degradation, and trigger costly unplanned outages. This technical report examines the quantifiable impacts of contamination on data center uptime, correlates industry failure data with established standards, and demonstrates the critical role of proactive decontamination and protective enclosures.

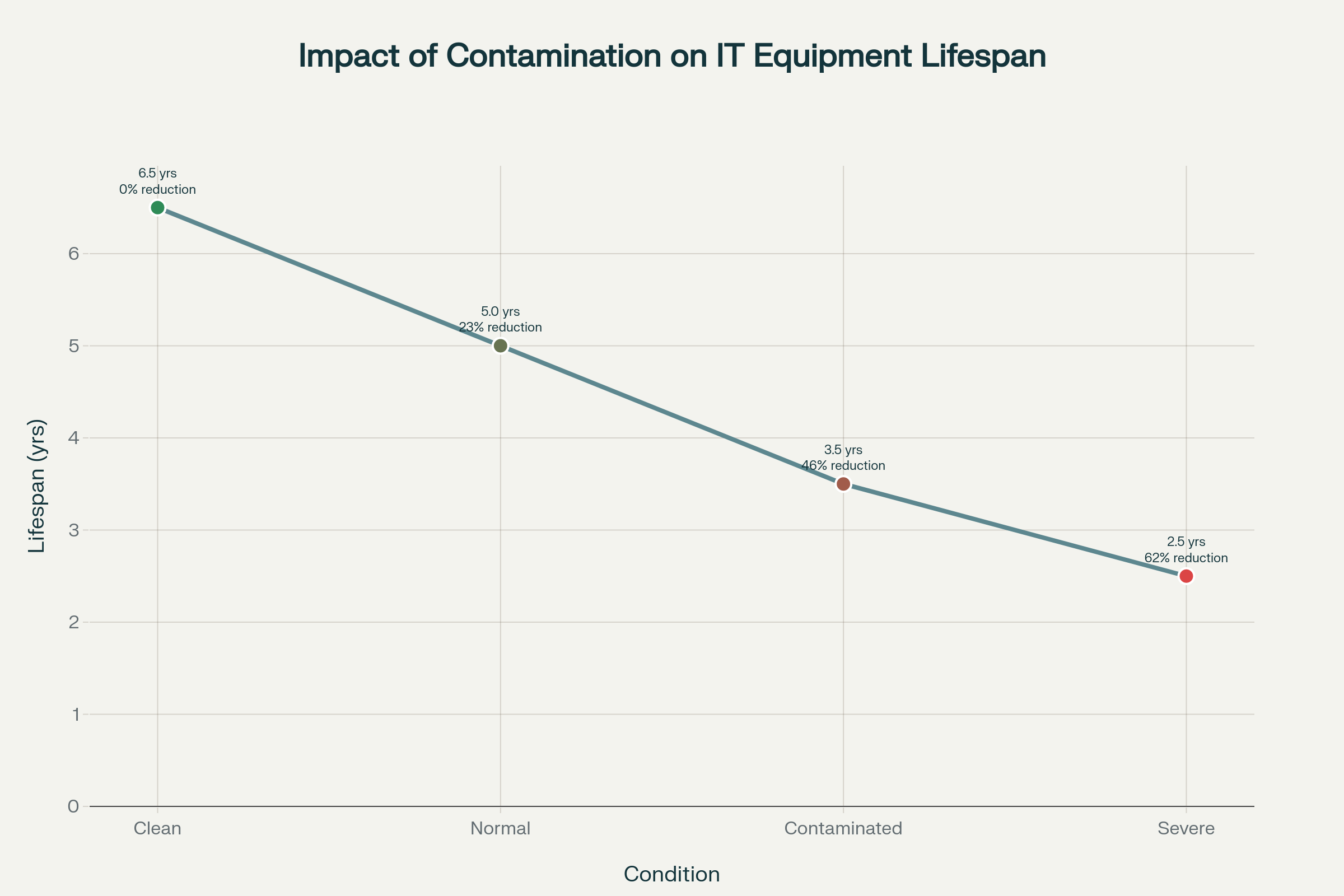

Data centers operating without comprehensive contamination control face equipment lifespan reductions from 5-7 years to 3-4 years—a 40-50% decrease in asset life expectancy. The financial consequences extend far beyond replacement costs. Organizations experiencing contamination-related failures report average downtime costs of $505,500 per incident based on a 90-minute outage duration, with 93% of enterprises reporting hourly downtime costs exceeding $300,000. For high-risk sectors, the stakes escalate dramatically: healthcare facilities lose $7,500 per minute ($450,000/hour), while financial services face $5,000 per minute losses.^1^3^5

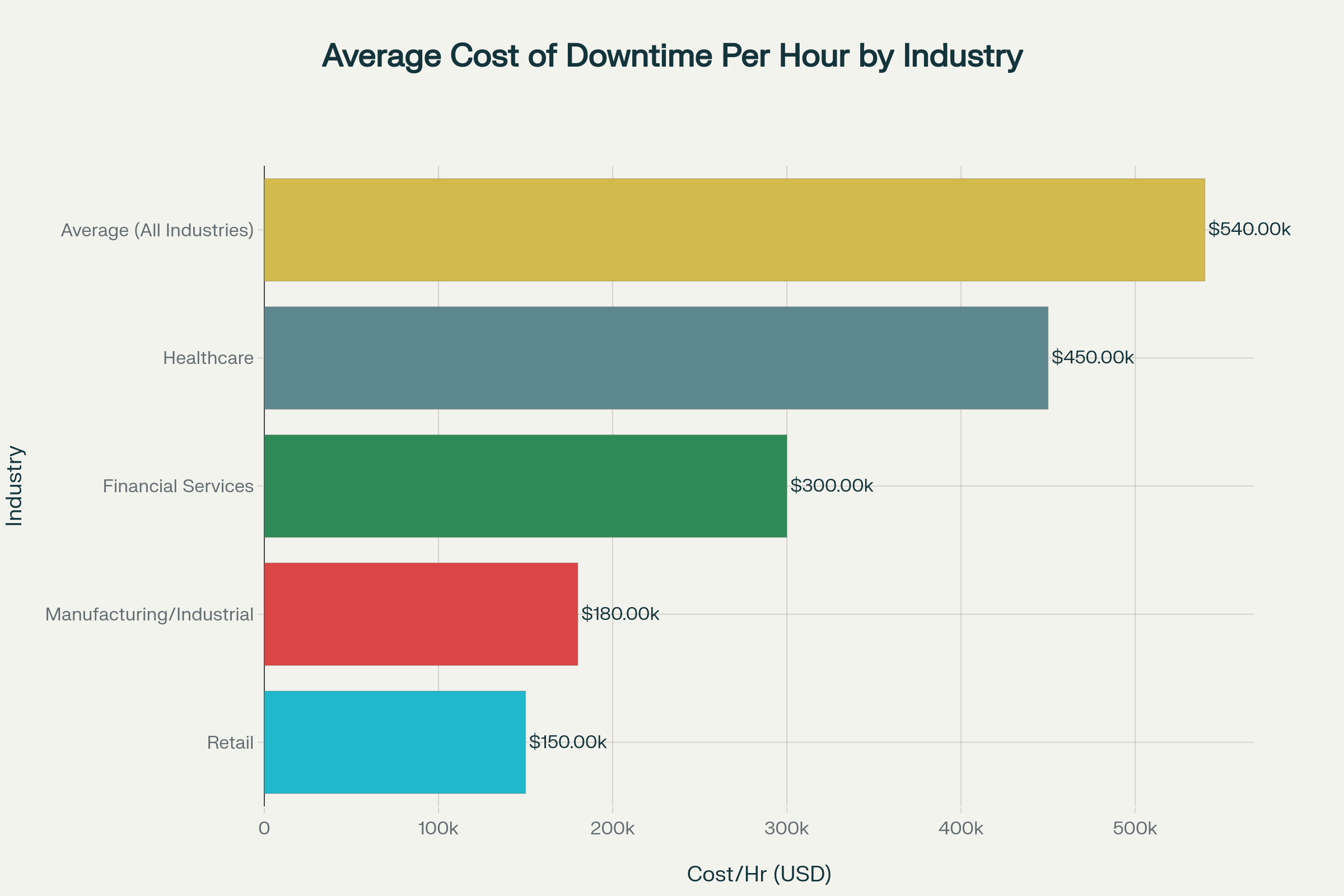

Comparison of average hourly downtime costs across healthcare, financial services, manufacturing, and other industries, showing healthcare at $450,000/hour and average enterprises at $540,000/hour.

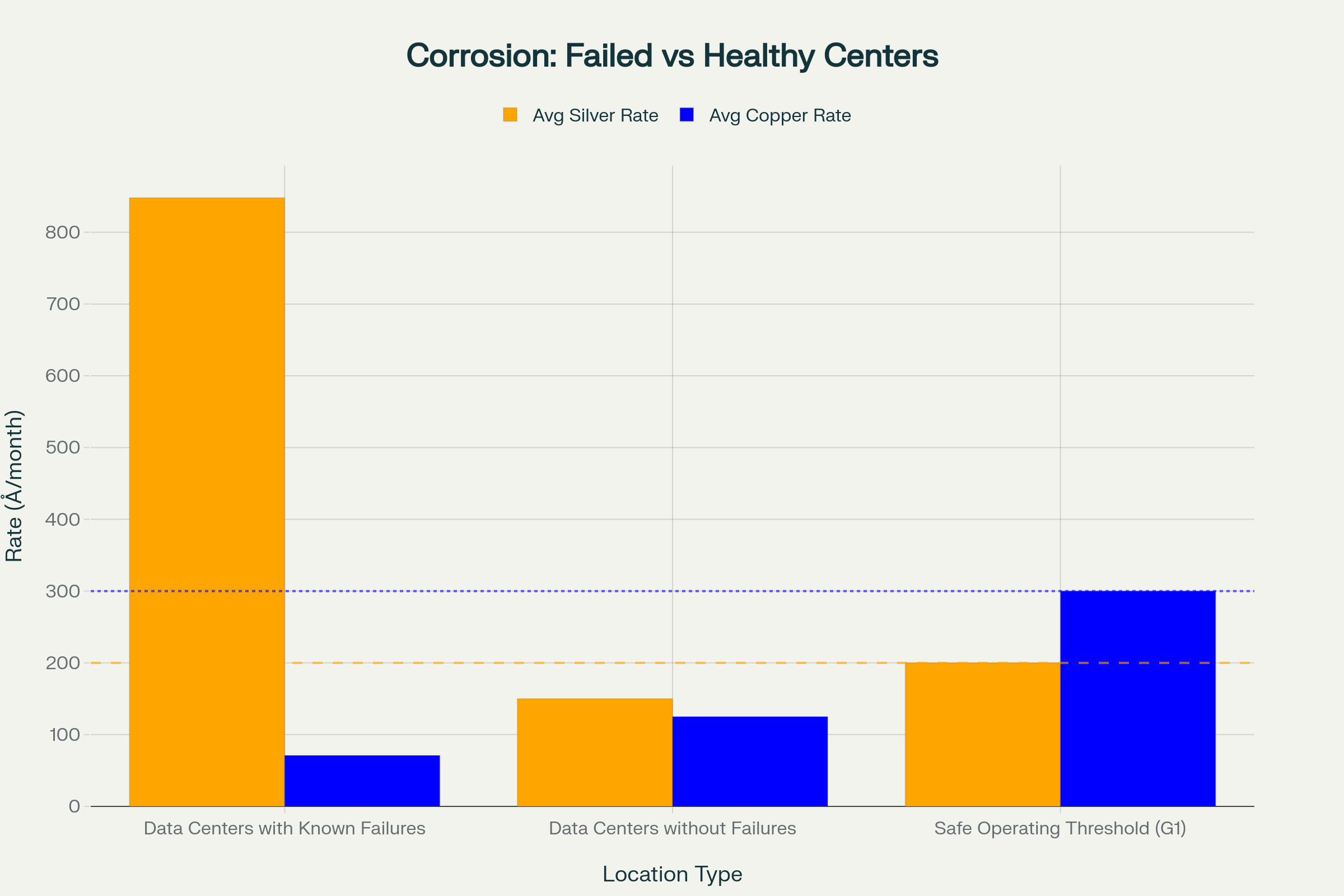

The correlation between contamination and equipment failure is unequivocal. In data centers with reported corrosion-related hardware failures, silver corrosion rates averaged 848 Ångströms per month—more than four times the safe threshold of 200 Å/month established by ISA Standard 71.04. These facilities experienced significantly higher failure rates across diverse equipment types, from power supplies to networking infrastructure.^7^9

Environmental contamination in data centers manifests through three interconnected mechanisms, each posing distinct threats to electronic infrastructure:

Airborne Particulate Matter

Particulate contamination encompasses dust, fibers, construction debris, and metallic particles ranging from 0.03 to 5 microns. The most damaging particles fall within the 0.5-5 micron range, small enough to penetrate cooling systems and settle on circuit boards yet large enough to bridge electrical contacts. Primary sources include outdoor air intake, HVAC systems, foot traffic, equipment maintenance activities, and building materials.^1

ASHRAE recommends data centers maintain cleanliness to ISO Class 8 standards, limiting particulate concentration to ≤3,520,000 particles ≥0.5 µm per cubic meter. Indoor dust demonstrates higher susceptibility to moisture-related failures compared to outdoor dust due to elevated concentrations of water-soluble salts including sulfates, ammonium compounds, sodium chloride, and potassium chloride. At equivalent deposition densities, indoor dust more readily induces surface insulation resistance loss, electrochemical migration, and accelerated corrosion.^10^11

Corrosive Gaseous Contamination

Sulfur compounds (H₂S, SO₂), chlorine (Cl₂), nitrogen oxides (NOₓ), and ozone (O₃) infiltrate data centers through air handling systems, originating from vehicle emissions, industrial processes, and power generation facilities. These gases react with metallic components—particularly copper traces and silver metallization—forming corrosive compounds that degrade electrical conductivity and increase resistance.^13^15

Critical failure thresholds occur when silver corrosion rates exceed 200 Ångströms per month or copper corrosion exceeds 300 Å/month. Data centers with corrosion-related equipment failures demonstrate silver corrosion rates averaging 848 Å/month (standard deviation 641 Å/month), representing an order of magnitude above safe operating thresholds.^16^17

Metallic Contaminants: The Zinc Whisker Phenomenon

Zinc whiskers—spontaneous crystalline growths emerging from electroplated steel surfaces—represent a particularly insidious contamination source in facilities utilizing raised floor systems installed 15-20+ years ago. These conductive filaments develop at approximately 250 microns annually, reaching lengths where they become airborne and infiltrate equipment through intake fans.^18^19

A single NASA data center experienced 10 catastrophic server failures and 12 router failures over 18 months, with investigation revealing zinc whisker densities reaching millions per 4-square-foot floor tile. One commercial facility reported 142 power supply failures attributed to zinc whisker contamination. The conductive nature of these metallic filaments causes intermittent short circuits, voltage variances, signal disturbances, and complete equipment failures when bridging exposed conductors.^8^19

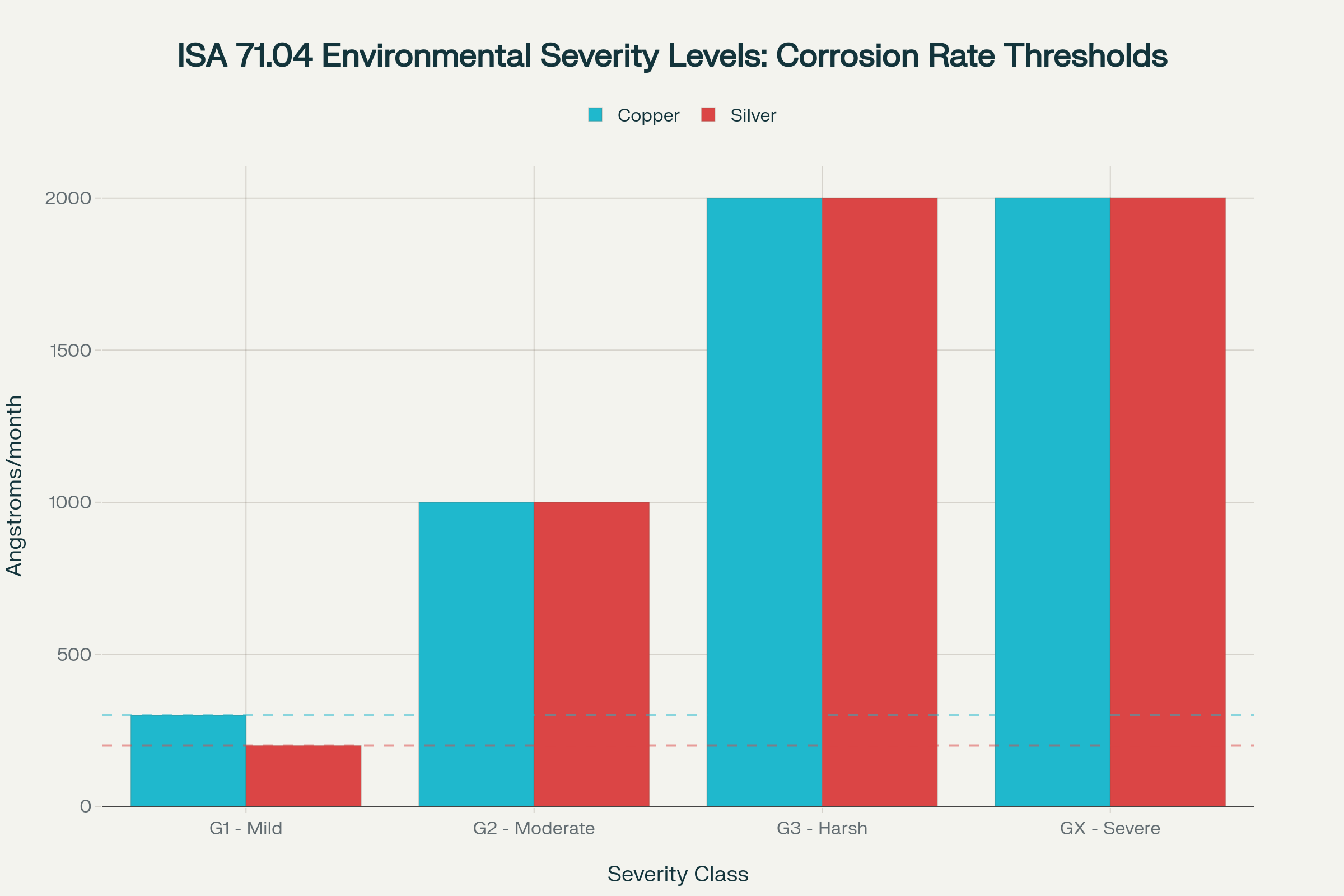

ISA 71.04 standard severity classifications showing maximum allowable copper and silver corrosion rates, from G1 (Mild) to GX (Severe), with critical failure thresholds marked.

ASHRAE and ISO 14644 Standards

ASHRAE Technical Committee 9.9 establishes environmental guidelines specifically for data processing environments, recommending ISO 14644-1 Class 8 cleanliness as the baseline standard. Achieving this classification typically requires:^10

The 2021 fifth edition of ASHRAE's thermal guidelines introduced critical updates acknowledging contamination's role in equipment reliability. While extending the recommended relative humidity range to 70% for low-contamination environments, the standard now requires facilities with corrosive gas concentrations above threshold levels to maintain humidity below 50%—below the previous 60% limit—to prevent accelerated corrosion.^16

ISA Standard 71.04-2013: Environmental Severity Levels

The International Society of Automation's Standard 71.04-2013 provides quantitative methodology for determining airborne corrosivity through reactivity monitoring. The standard classifies environments into four severity levels based on copper and silver corrosion rates measured over 30-day exposure periods:^17^24

The 2013 update to ISA 71.04 mandated silver corrosion monitoring as a required metric, recognizing silver's superior predictive capability for corrosion-related hardware failures compared to copper measurements alone. Leading IT manufacturers including Dell, IBM, Cisco, HP, Oracle, and others reference ISA 71.04 in site preparation guidelines and warranty compliance terms.^26^17

TIA-942: Telecommunications Infrastructure Standard

ANSI/TIA-942 provides comprehensive guidelines for data center design and implementation, covering architecture, electrical systems, mechanical design, fire protection, security, and contamination control. The standard emphasizes contamination control methodologies and monitoring programs to protect sensitive equipment. TIA-942 certification requires data centers demonstrate adherence to particulate and gaseous contamination guidelines aligned with ASHRAE and ISO standards.^27^29

Contamination as a Primary Failure Mechanism

Empirical data establishes contamination as a dominant contributor to premature equipment failure across multiple sectors:

For electronic equipment, studies demonstrate dust contamination can reduce useful life to less than half of manufacturer projections. Department of Energy research reveals equipment with contamination levels exceeding 500 µg/in² chloride equivalent experiences elevated failure rates if operated prior to contaminant removal. Conversely, reducing corrosive particulate concentrations below 20 µg/in² drives contamination-related failure probability to zero.^35

Comparison of corrosion rates showing data centers with equipment failures averaged 848 Å/month silver corrosion (4x the safe threshold), while healthy facilities maintained rates below 200 Å/month.

The Silver Corrosion Predictor

Analysis of 31 data centers with documented corrosion-related hardware failures reveals silver corrosion rates provide superior failure prediction compared to copper measurements. In these facilities:^7

Healthy data centers without known corrosion failures maintain silver corrosion rates averaging 140-350 Å/month and copper rates between 125-200 Å/month. The clear separation between failed and healthy facility corrosion profiles demonstrates no overlap in silver measurements, while copper measurements show significant overlap—confirming silver's reliability as a failure predictor.^26

Equipment lifespan comparison demonstrating that contaminated environments can reduce IT hardware life expectancy from 5-7 years to 2.5-3.5 years, representing a 40-62% reduction in asset longevity.

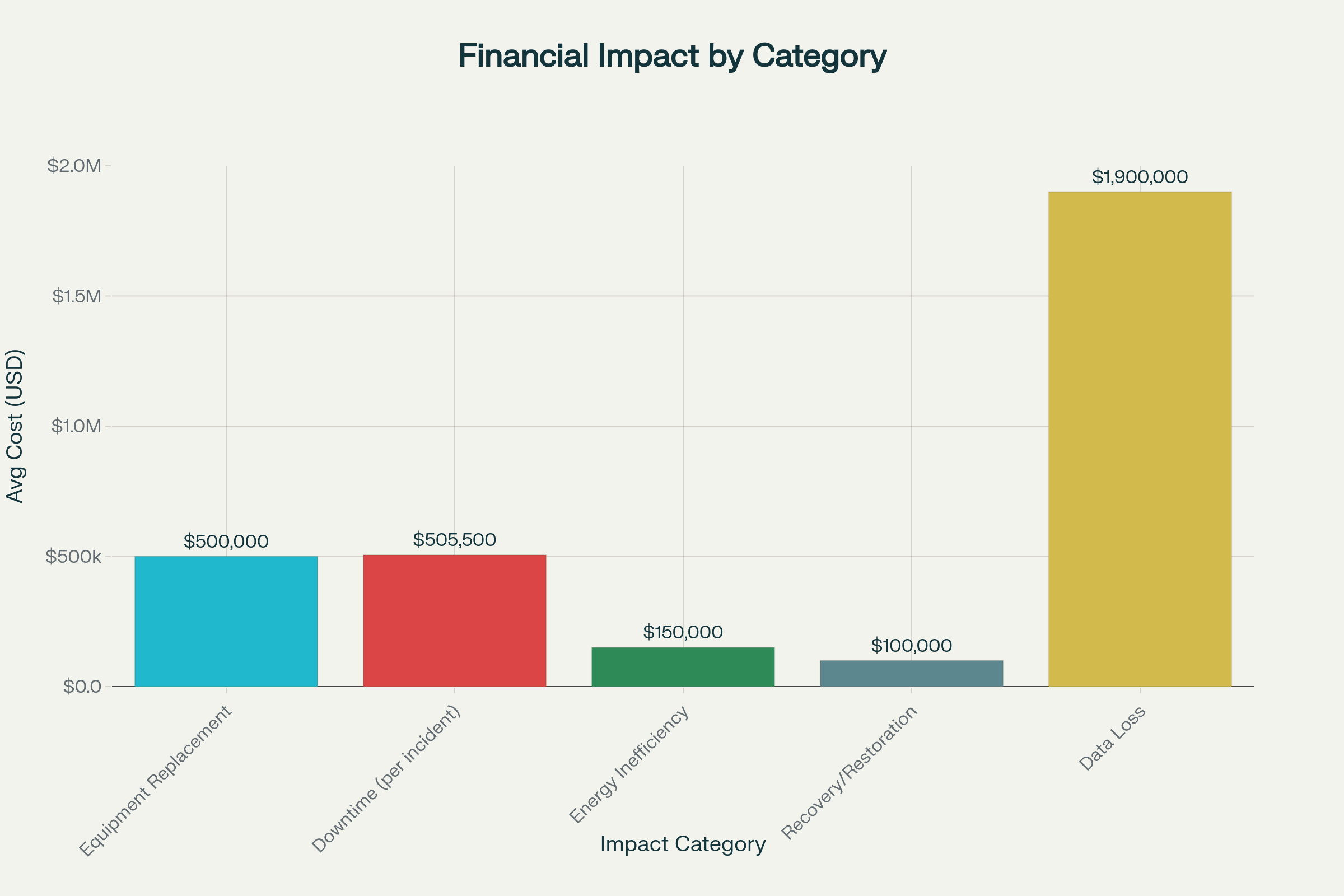

The financial impact of contamination-related outages varies significantly by industry vertical, reflecting differing dependencies on continuous operations and revenue generation models:^37^39

Healthcare Sector

Healthcare organizations face the steepest per-minute downtime costs among all industries. Electronic Health Record (EHR) system failures directly impact patient care delivery, with consequences extending beyond financial metrics to include delayed treatments, increased medical error risk, and potential patient safety incidents:^4^40

A single day of healthcare IT downtime can cost organizations approximately $1.9 million when accounting for lost revenue, inefficient operations, and potential regulatory fines. System disruptions prevent access to critical patient data including medical histories, prescriptions, and lab results, forcing healthcare providers to revert to manual processes while increasing error probability.^4

Financial Services

Financial institutions experience similarly severe downtime impacts due to 24/7 operational requirements and high-frequency transaction processing:^3

API downtime in financial services increased 60% between Q1 2024 and Q1 2025, with average uptime falling from 99.66% to 99.46%—translating to approximately 10 additional minutes of weekly downtime. Investment banks face heightened hourly costs due to high-frequency trading losses and real-time settlement disruptions.^3

Manufacturing and Industrial Sectors

While manufacturing downtime costs appear lower on a per-minute basis, the cumulative impact of contamination-driven equipment failures creates substantial operational and safety concerns:^44

Particulate contamination in manufacturing accelerates component wear, causes overheating through impeded airflow, triggers electrical malfunctions, reduces operational efficiency, and introduces product contamination risks. In food processing and pharmaceutical manufacturing, contamination incidents can compromise entire production batches, multiplying financial losses.^44

Average Cross-Industry Costs

Recent comprehensive analyses establish average enterprise downtime costs at:

Organizations experiencing downtime face costs extending beyond immediate revenue loss, including productivity losses, equipment damage, root-cause detection expenses, recovery actions, legal liabilities, and regulatory penalties. Equipment costs represent among the lowest expenses at approximately $9,000 per incident, meaning residual downstream effects prove far more costly than root cause remediation.^6

Healthcare facilities face compounding contamination vulnerabilities due to stringent uptime requirements, regulatory compliance obligations, and direct patient care impacts. Network failures disconnect vital medical devices from centralized systems, while data corruption complicates recovery efforts and threatens Electronic Health Record integrity.^4

Critical Vulnerabilities:

Beyond financial costs, contamination-driven downtime in healthcare creates reputational damage difficult to repair, as patients and referring physicians lose confidence in facility capabilities. The 80% of data center operators who believe better management would have prevented their most recent incident underscores the preventable nature of many contamination-related failures.^48^4

Financial sector data centers process billions of dollars in daily transactions, making them prime targets for contamination-related reliability risks. The sector's 24/7 operational requirements and real-time settlement systems leave minimal tolerance for equipment degradation:^49^50

Operational Impacts:

Financial institutions must comply with stringent regulations including GDPR and PCI DSS, with data centers providing the secure environment necessary for regulatory adherence. Contamination compromising cooling systems or causing equipment failures can trigger compliance violations, compounding financial and reputational damage.^43

Manufacturing environments present unique contamination challenges, as production processes themselves generate particulates while requiring reliable IT infrastructure for process control, inventory management, and automation systems:^44^52

Contamination Sources and Consequences:

Dust acts as an abrasive agent when combined with lubricants, accelerating wear on bearings, gears, and shafts—leading to premature component failure and reduced equipment lifespan. Accumulation on surfaces and in ventilation systems impedes airflow, causing machinery overheating and potential fire hazards. In food processing and pharmaceutical facilities, any degree of contamination can introduce product defects, compromising entire production batches and creating significant financial losses.^44

Sealed, rated enclosures provide the first line of defense against environmental contamination, creating protective barriers between sensitive electronic components and hostile atmospheric conditions:^53^55

NEMA-Rated Cabinet Protection

NEMA 12-rated cabinets offer comprehensive protection against dust, dirt, airborne particles, and light water exposure—ideal for warehouses, manufacturing floors, and unfinished areas where higher airborne contaminant levels exist. These enclosures feature:^57

NEMA 3R cabinets extend protection to outdoor environments, safeguarding against dust, dirt, rain, sleet, snow, and ice—critical for telecommunications installations and remote equipment locations. Properly specified sealed enclosures can reduce contamination exposure by 70% or more compared to standard ventilated cabinets.^54

Thermal Management in Sealed Environments

While sealed cabinets eliminate contamination ingress, they create thermal management challenges requiring specialized cooling solutions. Advanced enclosure coolers employ heat pipe technology, heat sink designs, and thermoelectric air conditioning without compressors or refrigerants. These systems maintain optimal internal temperatures while preserving environmental sealing, available in NEMA ratings 12, 3R, 4, and 4X for corrosive and wet environments.^55

Custom metal enclosures for data center applications provide electromagnetic compatibility (EMC), combining contamination protection with electromagnetic interference (EMI) shielding. Single integrated entry systems support EMC principles while protecting against fire, smoke, water, gas, and vibration—reducing space requirements by 70% compared to traditional cable gland installations.^56

Professional decontamination services extend equipment lifespan, maintain warranty compliance, and prevent costly contamination-related failures through systematic environmental control:^58^60

Comprehensive Service Components

Leading decontamination programs employ multi-faceted approaches targeting all contamination vectors:^59^58

Certification and Compliance

Professional services adhere to ISO 14644, ASHRAE guidelines, and industry-specific standards, ensuring data centers maintain required cleanliness classifications. Technicians utilize anti-static microfiber cloths, HEPA-filtered vacuum systems (99.97% efficient down to 0.3 microns), and continuous air scrubbing during cleaning operations to prevent contamination redistribution.^59^58

Post-service documentation includes humidity, temperature, and airborne particle count readings before and after cleaning, with comprehensive findings and recommended maintenance frequencies. This documentation proves critical for warranty compliance, as leading IT manufacturers require ISO Class 8 certification—facilities failing to maintain standards risk repair costs falling outside warranty coverage.^12

Economic Value of Preventive Decontamination

Department of Energy studies demonstrate equipment professionally decontaminated to below 20 µg/in² contamination levels achieve zero probability of contamination-related failure. Beyond preventing acute failures, decontamination removes accumulated operational dust and debris, returning surfaces to original cleanliness levels—potentially extending equipment lifespan beyond manufacturer projections.^35

The theoretical extended lifespan resulting from technical decontamination during the useful life period accounts for both failure probability elimination and operational improvement through accumulated contaminant removal. Given that contamination can reduce equipment lifespan from 5-7 years to 3-4 years (40-50% reduction), professional decontamination services delivering lifespan restoration provide substantial return on investment.^1

Proactive contamination management requires continuous or periodic assessment of environmental corrosivity using standardized measurement protocols:^17^24

Corrosion Classification Coupons (CCC)

ISA Standard 71.04-2013 specifies reactivity monitoring methodology employing copper and silver sensors exposed to the data center environment for 30-day periods. Analysis determines corrosion film thickness and chemistry using coulometric reduction techniques, classifying the environment into G1, G2, G3, or GX severity levels.^23^17

Silver reactivity monitoring provides complete accounting of corrosive chemical species present in the environment, including sulfur compounds, chlorine, and nitrogen oxides. Leading computer manufacturers require customers meet ISA 71.04 guidelines, limiting corrosive gaseous levels in data centers. Facilities should conduct coupon testing minimally twice annually—once in winter and once in summer—to detect seasonal variations in pollution levels.[^16]^63^64

Real-Time Atmospheric Monitoring

Advanced facilities employ continuous atmospheric corrosion monitors providing accurate, timely data on chemical filtration system performance and room air quality. Real-time monitoring enables immediate detection of contamination excursions, facilitating rapid response before equipment damage occurs.^17

Data center operators must exercise increased attention when corrosion levels approach action thresholds. For facilities testing with corrosion levels exceeding 300 Å/month copper or 200 Å/month silver, recommended moisture limits should decrease from 70% relative humidity to 50% RH to minimize corrosion acceleration.^22

Continuous particulate monitoring ensures data centers maintain ISO 14644-1 Class 8 cleanliness through real-time measurement and trend analysis:^12^66

Particle Counter Specifications

Compliance-grade particle counters measure size ranges from 0.3 µm to 25 µm, with flow rates optimized for cleanroom environments (typically 0.1 CFM / 2.83 LPM). Instruments must provide user-selectable particle size channels and mass concentration approximation reporting in µg/m³. Devices complying with ISO 21501-4 and JIS B9921 ensure collected data meets ISO standards for air cleanliness classification.^12

Certification and Warranty Protection

Regular particulate surveys enable facilities to issue certificates of conformity for audits and OEM warranty documentation. Top-tier IT hardware manufacturers including Cisco, Oracle, and Sun require Class 8 cleanliness as a warranty condition—particle contamination causing equipment failure in non-certified spaces results in repair costs falling outside warranty coverage.^12

Monitoring plans developed per ISO 14644-2 requirements must address:

Effective contamination management requires integrated approaches combining multiple protective mechanisms:^1^17

Tier 1: Source Control and Air Intake Management

Tier 2: Environmental Sealing and Enclosure Protection

Tier 3: Active Monitoring and Response Protocols

Tier 4: Scheduled Maintenance and Emergency Response

The business case for comprehensive contamination control becomes compelling when comparing prevention costs against failure consequences:

Prevention Costs (Annual)

Total Annual Prevention Investment: $55,000-$240,000 for comprehensive programs

Failure Costs (Per Incident)

Single Failure Event Total: $500,000-$3,000,000+

Organizations experiencing just one contamination-related failure every 5-7 years recover their entire annual prevention investment multiple times over. Facilities maintaining proactive programs extend equipment lifespan from 3-4 years (contaminated) to 5-7 years (clean), reducing capital expenditure cycles and delivering 40-50% improvement in asset utilization.^1

Leading IT equipment manufacturers explicitly reference contamination standards in warranty terms and site preparation guidelines:^68^12

Facilities failing to maintain specified environmental conditions risk:

Documented compliance through certified monitoring programs and professional decontamination records protects organizations against these risks while demonstrating due diligence to stakeholders, auditors, and insurers.^12

Environmental contamination in data centers represents a quantifiable, preventable threat demanding proactive management. Industry data unequivocally demonstrates the correlation between contamination exposure and equipment failure: facilities with corrosion rates exceeding ISA 71.04 G1 thresholds experience failure rates orders of magnitude higher than properly controlled environments.^1^26

The financial consequences of neglecting contamination control prove severe across all industry verticals. Healthcare organizations lose $7,500 per minute during outages, financial services face $152 million in annual downtime costs, and manufacturing facilities experience accelerated equipment degradation reducing operational efficiency. With average enterprises reporting downtime costs of $9,000 per minute and single incidents averaging $505,500, the return on investment for comprehensive contamination control programs becomes indisputable.^37^39^4^5

ASHRAE TC 9.9, ISA Standard 71.04, TIA-942, and ISO 14644 provide the framework for effective contamination management. Organizations implementing multi-tiered strategies—combining source control, environmental sealing, active monitoring, and professional decontamination—achieve dramatic improvements in equipment reliability, lifespan extension, and uptime performance.^58^12

The silent threat of contamination transforms into managed risk through vigilant monitoring, sealed protective enclosures, and proactive maintenance protocols. Data centers maintaining ISA G1 environmental conditions, ISO Class 8 particulate cleanliness, and scheduled decontamination services protect mission-critical operations while extending infrastructure investments by 40-50% beyond contaminated environment lifespans. In an era where digital infrastructure underpins every aspect of modern business, contamination control represents not merely a maintenance function but a strategic imperative for operational resilience and competitive advantage.^35

Breakdown of contamination-related costs showing data loss as the highest single-incident cost at $1.9M, followed by downtime at $505K per incident and equipment replacement at $500K.

[^63]: https://www.ashrae.org/file library/technical resources/bookstore/ashrae_storage_white_paper_2015.pdf

[^72]: https://www.ashrae.org/file library/technical resources/bookstore/supplemental files/therm-gdlns-5th-r-e-refcard.pdf

[^74]: https://www.ashrae.org/file library/technical resources/bookstore/ashrae_tc0909_power_white_paper_22_june_2016_revised.pdf

[^79]: https://www.ashrae.org/File Library/Technical Resources/Bookstore/ASHRAE_Storage_White_Paper_2015.pdf

[^80]: https://www.literature.mestek.com/dms/MestexMissionCritical/Qualitative Study of Cumulative Corrosion Damage.pdf

[^85]: https://karnodatacenter.com/files/TIA-942-B-2017 Rev Full.pdf